At a glance

Prototype production is a decisive point in efficient product development. In order to ensure the practice-oriented training of students completing the bachelor’s degree programme in Photonics, the Product Development and Laser Laboratory (PROLAB) was set up at the end of 2018.

Offer

A DATRON neo 4-axis milling machine was purchased in order work with various materials such as plastic, aluminium, wood or even steel. Thanks to the simple handling and integration of the 3D CAD systems, students can already produce prototypes independently and safely after just a few hours of training. The system is used both for project work during the upper semesters and for research projects.

We also offer the production of prototypes for optical components as a service. We would be happy to support you with your questions using our systems and expertise – get in touch with us.

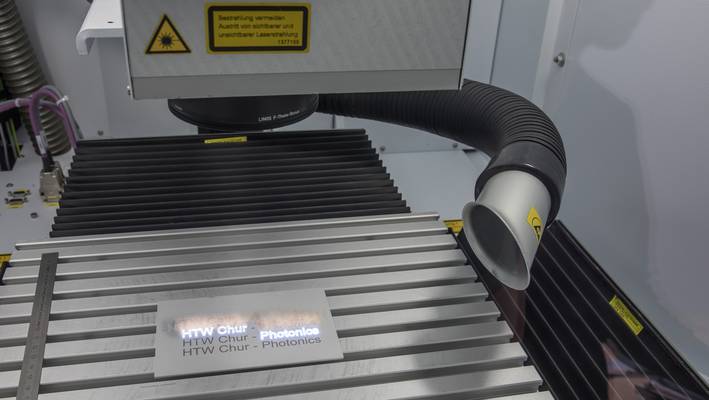

A TRUMPF laser marking system has also been added to the PROLAB. It can be used to engrave different materials and even cut thin sheets. Alongside the production of experimental materials, the system is also used for teaching laser technology.

A 3D printer and a reflow soldering oven including a paste printer are also available for prototype production.

Equipment

- DATRON neo+, compact CNC high-speed milling machine, including fourth axis

- TRUMPF TruMark Station 5000, laser marking system

- Reflow soldering oven LPKF ProtoFlow S/N2

- Stencil printer 3TSD360/U (paste printer)

- 3D printer MakerBot Replicator+

Further Information

Institute

Thethe Product Development and Laser Laboratory is assigned to the Institute for Photonics and Robotics (IPR).